DC Gear Motor Manufacturer

Who Is VoltSpin

VOLTSPIN is a leading DC Gear Motor manufacturer and supplier in China. We are committed to providing superior DC gear motor solutions to our global customers. At VOLTSPIN, we have extensive experience and expertise in supplying high quality micro gear motors for smart drive products in various industries.

Our Mission and Vision

Our Mission

VOLTSPIN's mission is to drive technological innovation and advancement across industries by providing our customers with high-performance, high-quality DC gear motors.

Our Vision

VOLTSPIN's vision is to be the world's leading provider of gear motor solutions that create lasting value and partnerships for our customers.

What Can We Do

At VOLTSPIN, we have always placed innovation and quality at the forefront of our efforts to provide customized solutions to our customers’ needs through the manufacture and sale of a diverse range of high-quality DC micro gear motors. Our product line covers a wide range of gear motor types, including but not limited to:

- Planetary Gear Motors: Provide powerful torque output through an efficient planetary drive design.

- Worm Gear DC Motors: play an important role when reduction ratios and high torque output are required.

- Spur Gear Motors: for applications where precision and smoothness are critical.

About DC Motor

Our motors range from φ10mm to φ51mm in diameter and cover a voltage range of 1V to 24V to meet the power needs of different applications. With our state-of-the-art manufacturing facilities and engineering expertise, we offer fully customized gear motors to meet your specific application requirements. Our motors are made from the finest quality materials and are 100% inspected before delivery to ensure consistent performance and reliability.

Whether in the fields of smart home appliances, medical equipment, power tools or automation, VOLTSPIN’s micro geared motors play a key role. Our products provide reliable drive solutions that give lasting impetus to technological innovation and development in a variety of industries.

Manufacturing Excellence

In our state-of-the-art facilities, we utilize advanced manufacturing techniques and rigorous quality control processes to ensure that every motor we produce meets the highest standards of excellence. From design to assembly, quality is at the heart of everything we do.

Advanced Facilities

Machining Shop: Equipped with the latest CNC machine tools and high-precision machining equipment for machining various metals and alloys.

Assembly Line: Automated assembly line for efficient production and assembly process.

3D Printing Studio: Equipped with advanced 3D printing equipment for rapid prototyping and customized parts production.

Manufacturing Technology

Numerical control machine tools (CNC) : through programming control, to achieve high-precision machining of parts.

Automated production lines: Reduce human error and increase production consistency and speed.

3D printing technology: For rapid prototyping and production of complex parts to shorten the design cycle.

Quality control process

Raw material inspection: Strict inspection and testing of incoming raw materials to ensure that their quality and performance meet the requirements.

Production process monitoring: real-time monitoring of the production process, timely detection and correction of production problems to ensure stable product quality.

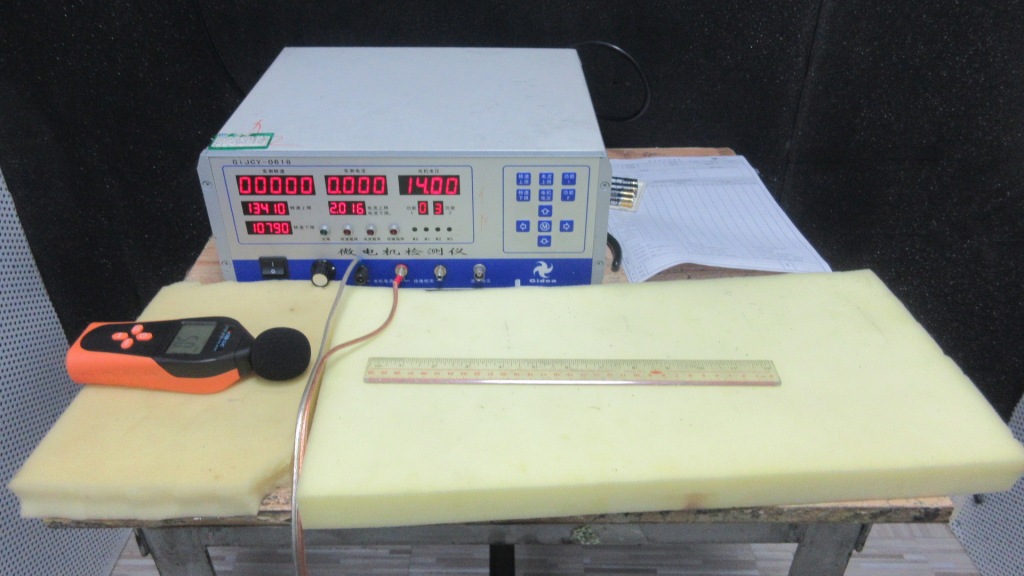

Finished product inspection: Complete inspection and testing of finished products, including appearance inspection, functional testing and performance verification.

Design to assembly

Product design optimization: Through advanced design software and simulation technology, optimize motor structure and performance to improve product quality and reliability.

Production planning: Develop detailed production planning and process flow to ensure smooth production process.

Assembly process control: design and optimize assembly process flow to improve assembly efficiency and product quality.

Quality Promise

our commitment

At VoltSpin, we see quality as the lifeblood of our business. We understand the importance our customers place on quality, which is why we take quality not only as a goal, but also as our commitment. We are committed to:

Strict quality management system: We have established a quality management system in line with international standards to ensure that quality standards and processes are strictly implemented in every link from product design to production and delivery.

Comprehensive testing procedures: We conduct comprehensive testing and verification of each motor, including performance testing, durability testing, environmental adaptability testing, etc., to ensure the stability and reliability of the product under various working conditions.

Exceed industry standards: We are not satisfied with merely meeting industry standards, but constantly strive to exceed them, striving to provide higher quality and more reliable motor solutions to meet our customers’ needs and expectations.

Quality management process

Our quality management process includes but is not limited to the following:

Quality control point establishment: Set up key quality control points in the production process to ensure that each link can find and correct problems in a timely manner.

Continuous improvement mechanism: We continuously evaluate and improve the quality management to ensure the continuous effectiveness and improvement of the quality management system.

Employee training and awareness: We attach importance to the quality awareness and skills training of our employees to ensure that each employee is able to understand and implement quality management requirements.

Quality assurance

We offer our customers not only products, but also a guarantee of trust and reliability. Whether in terms of product quality, delivery cycle or after-sales service, we always adhere to the integrity, reliability and responsible attitude to provide customers with the best quality motor solutions.

LEAVE US A MESSAGE

If you want to enquire or have any questions, please fill out the form below and we will contact you as soon as possible.