Planetary Gear Motor Manufacturer in China

As a leading DC planetary gear motor manufacturer, we adhere to the concepts of excellence, reliability and innovation to provide high-performance power solutions to customers around the world.

Voltspin Custom Planetary Gear Motors

You Design, We Manufacture

Tell us your needs and Voltspin will tailor a planetary gear motor that meets your requirements. Whether you need a high-speed micro motor, a long-axis design, or a planetary gear motor that adapts to special environments, such as waterproof, low noise, etc., Voltspin can meet your unique needs. Our planetary gear system ensures efficient transmission and precise control.

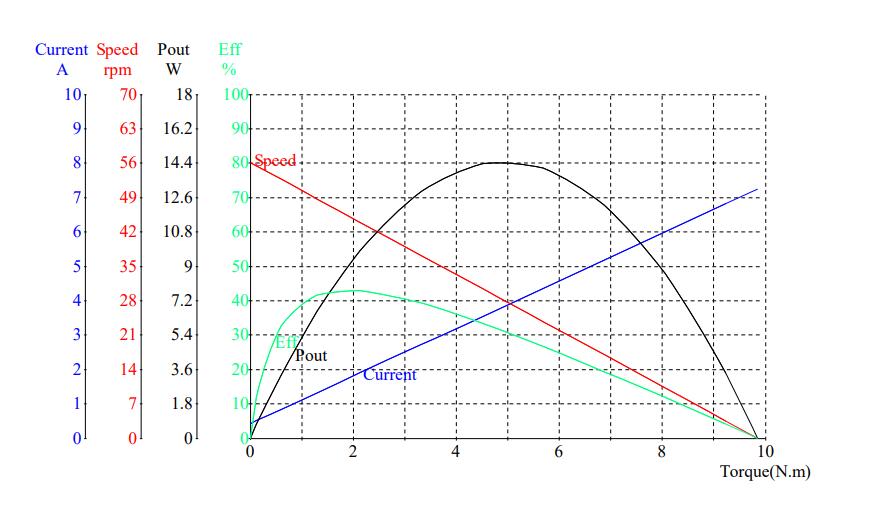

Benefits of DC Planetary Gear Motors

- High Efficiency, Precision, Torque: Motors boast high efficiency, precision, and torque, with low noise and minimal backlash for reliable performance.

- Durability and Efficiency: Designed for longevity and consistent operation, these motors are built to last with high efficiency.

- Compact, Customizable Design: Featuring a compact size, durable gears, and customizable shaft options to fit specific application needs.

- Durable, Waterproof, Long-Lasting: Motors are crafted for durability, waterproof to withstand harsh conditions, and offer a long lifespan.

- Speed Range, Planetary Resilience: Offering a broad speed range with a robust planetary construction for versatile and dependable performance.

Why Choose VoltSpin As Your Planetary Gear Motor Supplier

Solving the Gear Broken Problem

We utilize high-strength materials such as alloy steel and engineering plastics for the gears, significantly improving their durability and wear resistance. Our optimized gear designs ensure even load distribution, effectively reducing stress concentrations. This minimizes the risk of fractures, even under high torque and speed conditions. As a result, our motors offer consistent and reliable gear performance, enhancing the overall longevity and reliability of the system.

Reducing Noise

Precision manufacturing of gears minimizes manufacturing errors, leading to smoother meshing and reduced friction, which significantly lowers operational noise. Additionally, we optimize transmission systems and use flexible connections to absorb vibrations, further mitigating noise propagation for quieter performance.

Providing More Torque at the Same Dimension

Our high-efficiency motor designs increase torque output without enlarging the motor size. By refining planetary gear transmission systems with more gears and optimized ratios, we achieve higher torque transmission efficiency and load-bearing capacity, meeting compact high-torque requirements.

Expert Evaluation and Tailored Solutions

Our team provides thorough professional evaluations to understand the unique challenges and requirements of your application. With in-depth expertise in miniature motors, we deliver customized solutions designed to optimize performance, efficiency, and longevity. Whether it’s refining motor design, adjusting specifications, or offering technical guidance, we ensure that every solution is perfectly aligned with your needs for reliable, long-term operation.

Extended Life-span for Reliable Performance

Our miniature DC motors are engineered for exceptional durability, ensuring a long life-span even under challenging operating conditions. By using high-quality materials, precision manufacturing, and advanced design techniques, we minimize wear and tear on critical components. This results in consistent, reliable performance over time, reducing maintenance needs and enhancing the overall value of the motor. Whether in high-torque or high-speed applications, our motors are built to last, providing you with long-term reliability and performance.

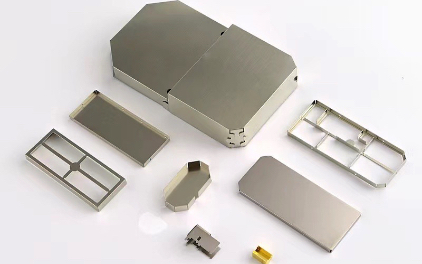

Effective EMI and EMC Shielding for Stable Operation

Our miniature DC motors are equipped with advanced EMI (electromagnetic interference) and EMC (electromagnetic compatibility) shielding solutions to ensure stable and reliable performance. We use high-quality materials, such as copper and aluminum foil, along with optimized shielding structures, to effectively minimize electromagnetic interference. This enhances electromagnetic compatibility, ensuring smooth operation even in environments with high electromagnetic activity. By reducing the risk of interference, our motors maintain consistent performance and prevent malfunctions, making them ideal for sensitive applications.

What Our Customers Say?

Every question you have, they ask and solve and placed orders.

Let’s see what they want to know. It would be great help for your small dc motor decision.

Frequently Asked Questions

A planetary gear motor is a type of gear motor that uses a central sun gear surrounded by planet gears, all encased in a ring gear. This arrangement allows for high torque transmission and compact design, making it ideal for applications requiring precision, efficiency, and durability.

A planetary gear motor works by having a central sun gear that drives surrounding planet gears, which in turn mesh with an outer ring gear. This configuration allows for high torque and smooth power transmission, as the load is evenly distributed among the planet gears.

The purpose of a planetary gear is to distribute load evenly across multiple gears, providing high torque and reducing wear and tear. This design results in efficient power transmission and a compact size, suitable for applications that need precise control and high power density.

No, planetary gears are generally quieter than other gear types due to their balanced load distribution and smooth operation. The design helps minimize noise and vibration, making planetary gear motors suitable for applications where quiet operation is important.

LEAVE US A MESSAGE

If you want to enquire or have any questions, please fill out the form below and we will contact you as soon as possible.