DC Worm Gear Motor Manufacturer in China

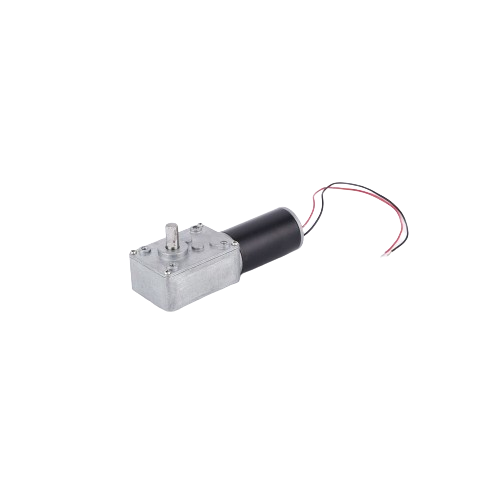

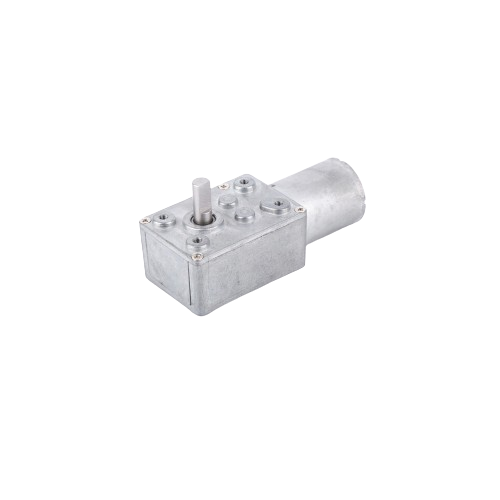

VoltSpin Products’ worm gear DC motors are miniature worm gear motors consisting of a worm gearbox and DC motor with high torque transmission, compact design and self-locking capability for a wide range of industrial and technological applications. We are known for providing highly customized motor solutions to meet our customers’ diverse power, speed and size requirements. Tell us what you need and we will give you the perfect solution.

Voltspin Custom Worm Gear Motor

You Design, We Manufacture

Voltspin designs and manufactures DC spur gear motors. We can customize tiny reduction motors to meet your application according to customer needs. Whether you need a spur gear motor with low torque and speed, or you are looking for precision cut gears, Voltspin can meet your needs. We provide spur gear motors with various reduction ratios, voltages and sizes.

Power Range

Provide a variety of power options from 1 W to 500 W to meet the needs of different applications.

Voltage Options

Support a variety of voltage configurations, including 3V, 6V, 12V, 24V, etc., suitable for a variety of power environments.

Waterproof and Protection Level

Different protection levels are available, including IP54, IP65, IP67, to ensure the reliability of the motor in harsh environments.

Speed and Torque

Different speeds (such as 2000 RPM, 3000 RPM, etc.) and torque options are provided according to requirements to meet specific application performance.

Mounting

Multiple mounting options are available, including different sizes, shapes and mounting hole locations for easy integration with equipment.

Special Requirements

Other parameters such as noise level, temperature range, etc. can be customized according to customer needs.

What our customers say?

Every question you have, they ask and solve and placed orders.

Let’s see what they want to know. It would be great help for your small dc motor decision.

FAQ

Frequently Asked Questions

A worm gear motor is a type of gear motor where a worm (a gear in the form of a screw) meshes with a worm gear (similar to a spur gear). This design allows for high torque transmission and precise speed control in a compact form, making it ideal for various applications requiring reliable and smooth operation.

The purpose of the worm gear is to transfer motion and power between non-parallel and non-intersecting shafts, typically at a right angle. It provides significant speed reduction and increased torque in a compact size, which is crucial for applications requiring precise movement and high torque in a small space.

The lifespan of a worm gear motor depends on factors like usage, maintenance, and operating conditions. With proper care and regular maintenance, a high-quality worm gear motor from VoltSpin can last many years, providing reliable performance in various applications.

Worm gear drives offer several advantages, including high torque output, smooth and quiet operation, compact size, and the ability to achieve significant speed reduction. They also provide self-locking capabilities in many designs, preventing back-driving and enhancing safety in various applications.

A worm gear motor works by having a worm, which is a shaft with a screw-like thread, engage with a worm gear, which looks like a spur gear. When the worm rotates, it turns the worm gear. This interaction allows for high torque transmission and significant speed reduction, suitable for various mechanical applications.

Worm gears are commonly made from materials such as bronze, steel, and cast iron. The worm is usually made of hardened steel to ensure durability, while the worm gear is often made of a softer material like bronze to reduce friction and wear, providing a longer lifespan for the motor.

Choosing the right worm gear motor involves considering factors like the required torque, speed, power, and the environment in which it will operate. It’s important to match the motor’s specifications with the application’s needs to ensure optimal performance and longevity. Consulting with a supplier like VoltSpin can help determine the best fit.

Worm gear motors require regular maintenance, including checking for lubrication, inspecting gears for wear and tear, and ensuring that all components are properly aligned. Periodic maintenance ensures the motor operates smoothly and extends its lifespan, reducing the risk of unexpected breakdowns.

Worm gear motors are typically not used for high-speed applications because they are designed for high torque and significant speed reduction. They are best suited for low to moderate speed operations where precise control and high torque are essential.

The self-locking feature in worm gear motors prevents the output shaft from being driven backward by the load when the motor is not powered. This feature enhances safety and reliability in applications where holding a position without back-driving is crucial, such as in lifts and hoists.

LEAVE US A MESSAGE

If you want to enquire or have any questions, please fill out the form below and we will contact you as soon as possible.